nanobubble generator

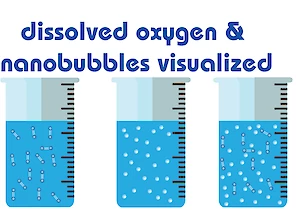

A nanobubble generator, or, as it should be called according to ISO standards, an ultrafine bubble generator, is a device that mixes water and a gas to produce nanobubbles. Nanobubbles should be smaller than 200 nanometers to be called a nanobubble. Since 200 nanometers is quite large to be considered nanoscopic, the name "nanobubbles" is not entirely appropriate. For this reason, the ISO has named a nanobubble an ultrafine bubble. The naming convention follows the same names as for particles.

There are two types of nanobubble generators. First, there are gas-water circulation types of nanobubble generators. Second, there is a gas-water pressurization-decompression, also often referred to as a pressurized dissolution type of nanobubble generator. All units are based on one principle or the other, or a combination of both. In the gas-water circulation type, the gas is introduced into a water vortex, and the gas bubbles are formed by breaking the vortex. In the pressurized dissolution method, approximately 5% of the gas is dissolved under pressure in water, creating a supersaturated solution. When the water is depressurized, the gas escapes from the water and forms nanobubbles. It's like opening a bottle of beer or a can of Coke; the liquid in the bottle is depressurized, and bubbles form. The pressure in a beer or Coke is too low to form any nanobubbles.

Acniti sells nanobubble generators of the gas-water circulation type, which we have branded as the turbiti series. Acniti also sells pressurized dissolution nanobubble generators, branded as GaLF. GaLF stands for Gas Liquid Foam.

Links

The turbiti nanobubble generator is a first-class workhorse. Turbiti can be placed in the most demanding environments. The nanobubble generator requires a low head pump, so it's efficient in energy usage. Combined with the benefits of a static mixer, Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti into their own equipment. The Turbiti concept gives you a worry free nanobubble solution.

Acniti is a Japanese manufacturer specializing in nanobubble equipment and industrial oxygen concentrators. Based in Osaka since 2017, we are the only provider offering three distinct nanobubble generation technologies: pressurized dissolution, turbulent static mixer, and hammer-mill rotation. Our solutions serve universities, water treatment, aquaculture, agriculture, mining, wastewater remediation, and industrial cleaning applications globally. Acniti products integrate robust PSA oxygen concentrators with proprietary nanobubble generators for 24/7 industrial operation. Acniti does not supply oxygen concentrators for medical purposes.

There are various technologies to generate nanobubbles (ultrafine bubbles). This article gives an overview of the most used techniques, such as pressurized dissolution, static mixers, and rotational flow.

The ozone nanobubble mixer is a nanobubble generator which is specifically designed for the use with ozone. Research with universities has shown, that ozonated nanobubble water, keeps longer its ozone residue in the water than when it is used only with a venturi also the amount of ozone gassing out is reduced.

Combined with the benefits of a static mixer Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively ozone nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti ozone technology into their own equipment and sell nanobubbles generator equipment under their own brand name. This product is only for dealers and partner of acniti, that have a license agreement and commit to buy certain quantities.

Customized GaLF solutions built into your own applications, this is a stainless steel model. Suitable for hydrogen and gasoline.

Discover how the Turbiti submersible nanobubble mixer revolutionizes water treatment, agriculture, and aquaculture with its reliable oxygen-saturation technology. Built from corrosion-resistant 316L stainless steel and marine-grade plastics, this unit is easy to install, enhances water quality, boosts productivity, and adapts to your needs. Learn more about its versatile applications and robust design—read the full details on the page.

High-efficiency industrial ozone nanobubble generator using hammer-rotation technology. Achieve maximum ozone dissolution with zero turbulence and low energy. Ideal for food safety, water treatment, and research.

Learn how the Complutense University of Madrid uses Acniti nanobubble technology to increase wastewater treatment efficiency and remove emerging contaminants. The research highlights that this technology enhances plants without requiring major infrastructure investments—a significant pain point for municipality and industrial plant managers.

Discover the ultrafine GaLF, a cutting-edge generator delivering the highest concentration of nanobubbles in the Finebubble industry. Designed for researchers, universities, and labs, it’s perfect for fundamental research and product development. With advanced PLC controls and flexible gas options, this compact and robust unit ensures peak performance and easy operation. Read more to see how nanobubbles can boost cleaning, plant growth, and fish health.

Discover how three Japanese flower growers revolutionized their cultivation with Acniti's turbiti nanobubble technology. Learn about improved root development during hot summer planting seasons and increased winter harvests that deliver payback in just 1-2 seasons.

The ultrafine miniGaLF is an entry-level GaLF nanobubble generator for research, designed for universities, laboratories, and OEMs who want to explore ultrafine bubble technology. It connects directly to a water tap and gas source and can be configured with a Plus recirculation option to achieve higher ultrafine bubble concentrations for water treatment, aquaculture, agriculture, and product development.

A temple with a beautiful moat in Kyoto, Japan had a group of volunteers maintaining the moat, by cleaning it and doing regular maintenance. Due to the older age of the volunteers, the group stopped moat maintenance around 1998. In the next 20 years no maintenance was done and year by year the situation worsened on one hand natural pollution wasn't removed such as leaves in autumn and excessive uncontrolled water plants growth took place. On the other hand, tourism in Kyoto was on the rise and more and more, litter came in the moat. This led to an uncontrolled situation of bad smell, fish mortality opaque water and the bottom of the moat was invisible. In the summer, algal blooms were becoming more and more frequent.

The agriGaLF 60 is a pressurized dissolution nanobubble generator with a water flow of 100 LPM (6 m³/hr) and gas flow of 4 LPM at 130 kPa. Designed for agricultural and water treatment applications, it runs on 3-phase 200–240 VAC and supports non-corrosive gases including oxygen, nitrogen, CO₂, and ambient air.

The agriGaLF 120 is an industrial nanobubble generator using pressurized dissolution technology to produce ultrafine bubbles at 200 LPM. Designed for continuous operation in agriculture, aquaculture, and water treatment, it supports O₂, CO₂, N₂, and ambient air. Full metric and imperial specifications below.

The Turbiti Fusion 707 is a compact micro nanobubble generator designed for laboratory and small-scale industrial applications. Using turbulent mixer ejector technology, it delivers 9–15 LPM liquid flow with O2, air, CO2, or N2 gas inputs. Built with a stainless steel pump at 230V, it is ideal for aquaculture, water treatment research, and process development.

The Turbiti Fusion 808 115V is a compact, lab-scale nanobubble generator engineered for ozone and multi-gas applications. Using turbulent mixer ejector technology, it delivers 9–15 L/min water flow with a 550W stainless steel pump. Compatible with O2, air, CO2, N2, and O3. Designed for research labs and small-scale industrial installations requiring reliable 115V nanobubble generation.

The Turbiti Fusion 808 230V is a compact nanobubble generator designed for lab and small-scale industrial use. Using turbulent mixer ejector technology, it handles O2, O3, CO2, and N2 gases at flow rates of 9–15 LPM. The stainless steel pump makes it ideal for demanding ozone applications in water treatment and research.

Explore groundbreaking research on air nanobubbles and their revolutionary impact on oxygen transfer in wastewater treatment systems. This comprehensive study reveals how nanobubble technology achieves six times faster dissolved oxygen increases compared to conventional aeration methods, offering significant energy savings and enhanced treatment efficiency. Learn about the experimental results using Acniti's Microstar Nanobubble Generator, which demonstrates improved oxygen mass transfer coefficients and optimal bubble size distribution.

Ebara DWO 400 for nanobubble generator turbiti 737 and small 747 applications