Published: Thursday, 13 June 2019

Modified: Friday, 14 July 2023

High concentration nanobubble generator selector

Acniti is specialized in the sales and marketing of ultrafine bubble equipment and nanobubble technology. When you shop for a nanobubble generator there are two aspects of importance, the amount of water you want to treat and the amount of gas that needs to be dissolved in the liquid and the concentration of bubbles that you want to create in the water. It is always important to realize the distinction between dissolved gasses and ultrafine bubbles. Bubbles are gas-filled cavities in a liquid which remain suspended for a long time in water. A dissolved gas in water is an unbound molecule. Unbound molecules and gas-filled cavities behave differently in liquids.

Acniti supplies multiple lines of ultrafine bubble generators. GaLF is the name of the high concentration ultrafine bubble units (see table 2 and 4) or microStar for the corrosive environments. Turbiti nanobubble mixers are the large-water volume units (see table 1 and 3). This article focusses on the GaLF and microStar high gas concentration units (see table 2 and 4) and not on the nanobubble mixers which produce a lower concentration of ultrafine bubbles but move high volumes of water.

table product lines

| Low gas concentration | High gas concentration | |

|---|---|---|

| Low water volume | mini-nanobubble mixer (1) | GaLF high concentration units (2) |

| High water volume | nanobubble mixer series (3) | GaLF production units (4) |

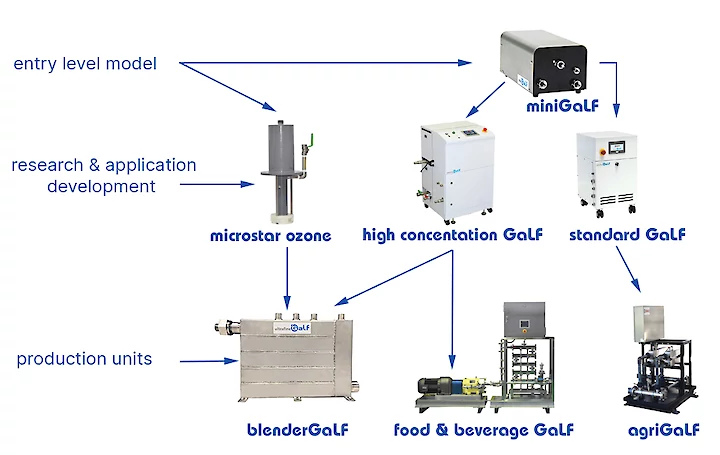

The GaLF high concentration line of ultrafine bubble generators can be further divided into 4 different types: the entry level unit machines, the research and development unit machines and the production units.

GaLF high concentration units

miniGaLF

On the entry level acniti offers the miniGaLF. The miniGaLF is a good starting point for application development or research purposes and is economically priced. Connect the unit directly to the faucet and you can start producing ultrafine bubbles. When the requirement is higher concentrations of ultrafine bubbles, this is possible by connecting a pump, (miniGaLF plus) and have the water circulate multiple times through the ultrafine bubble generator.

microStar

The microStar ozone is an entry level model, but also can be perfectly used for application development. The unit excels in ozone nanobubbles, and other corrosive environments. The unit has a record of accomplishment in the oyster industry where it is used to disinfect life shells which have a virus or bacterial infection. Further this unit has a large potential in the food industry for CIP cleaning. The microStar does not use a pump but uses a stirring technology. This benefits applications where it is difficult to use a pump.

standard GaLF

The standard GaLF strikes the balance between the miniGaLF and the high concentration GaLF. Its more convenient to use than the miniGaLF because it includes a pump and a control plc, but the unit is not as powerful as the high concentration GaLF. The unit is suitable for Air, Oxygen and CO2. It cannot handle corrosive gasses.

high concentration GaLF

The high concentration GaLF is the top model producing the highest concentration of ultrafine bubbles in the industry. This unit uses a more advanced mixing technology in combination with an extraordinary strong pump for pressurization of the mixing box. We recommend this unit for projects which requires the highest concentrations of nanobubbles. The high concentration GaLF can handle air, CO2 and O2 for producing billions of nanobubbles.

GaLF production units

Most clients after working with one of the above research and development units and after developing successful their application are in the need to scale up. In general, there are two routes to go from here, have a custom unit built by acniti or built your own unit using the patented blenderGaLF mixing boxes.

blenderGaLF

The blenderGaLF is used by customers that want to build their own nanobubbles solution for their own industry product application. Customers using the blenderGaLF are remarkably diverse, like agriculture, fish cultivation and industrial purposes such as washing cleaning, disinfection, and dissolved air flotation DAF.

food and beverage GaLF

The food and beverage GaLF is a custom built project for .i.e. a water bottling company that needs a unit that can be used in the food industry. The food industry demand high hygiene and cleaning standards. For this reason, we developed an ultrafine bubble generator with a cleaned in placed technique (CIP). Now clean the ultrafine bubble generator without having to disassemble the unit which safes a lot of downtime and labor. These kinds of projects have awfully specific requirement and they are always done, by making project drawing, the project drawings need approval from the customer before the unit is built. After building the unit it gets vigorously tested before its installed at the customer after which training of the staff takes place.

agriGaLF

The agriGaLFis one of the first developed machines and before we named it agriGaLF it has been extensively used in soil-remediation projects. Cleaning polluted soils from petrol stations and old factories. We built the agriGaLF in 4 different sizes. In recent years, many agricultural projects use the agriGaLF for the improvement of irrigation water or fish cultivation. The specific about the agriGaLF is that it does not heat up the water as much as the other high concentration ultrafine bubble generators. Most of the units increase the temperature in one pass by 0.5 to 1°C, the design of the AgriGaLF is in such a way that there is only a minimal temperature increase of around 0.07°C. Since the in introduction of the turbiti submersible UFB mixer many customers opt for this unit as it is more economical and it's easy to combine with an industrial oxygen concentrator.

Ultrafine bubbles applications

In the above you could see the assortment of ultrafine bubble generators that have all their own strengths and care for their specific application in the industry.

the high concentration low volume applications

- most research by universities and research institutes investigating fundamentals of ultrafine bubbles

- food and drink applications

- washing of electronics

- sleeping fish transport concept (living fish transport)

- agriculture and greenhouse projects

- dental applications cleaning and sterilization

- CNC milling and drilling coolant applications

- mining recovery

- ozone applications with high free radical content

- applications with fast retention times

- small space applications

- degassing of wine

the high-volume lower concentration applications

- lake and pond remediation

- algae reduction

- algae cultivation

- wastewater applications

- swimming pools oxygenation to reduce chloride usage

- agriculture and greenhouses

- fish cultivation in open ponds

- shrimp cultivation

- drinking water for poultry cattle and pig farming

- high volume ozone applications

- applications with slow retention times