Published: Saturday, 22 April 2023

Modified: Friday, 22 September 2023

Nanobubbles and Its positive Effects On the Mechanical Strength of Concrete

Introduction

Concrete is one of the main used building materials, and it is nearly impossible to replace concrete with other natural materials. Cement is the main part of concrete preparation. However, the energy consumption of the cement industry consumes large quantities of fossil fuels and create serious environmental issues including air pollution, climate change and global warming by continuously emitting carbon dioxide (CO2). For example, about 900 kg of CO2 is emitted when one ton of cement is produced, which means, almost two-thirds of global CO2 emissions are generated by cement industries. Thus, eco-friendly alternative materials and systems need to be developed and evaluated to decrease the global warming and other environmental issues.

For the first time, nanotechnology was introduced by Richard Feynman. In December of 1959, He gave a talk called “There’s Plenty of Room at the Bottom” and introduced the nanotechnology.

Nanobubbles are very small bubbles with a diameter of less than 200 nm and can remain in water for a long time. Nanobubbles technology is wildly use in various fields, such as surface coating and cleaning, removal of pollutants, water treatment, biomedical and contraction engineering, improving the flotation of ultrafine minerals, and the release of energy when the bubbles collapse and destroyed.

The importance of nanobubbles on the strength of cement mixture

As mentioned before, nanotechnology is an emerging branch of science related to understand and control making materials in nano dimensions. Study of concrete and paste cement in microscopic and macroscopic scales is important for the development of new building materials and their application.

The strength of a cement mixture can be improved through adding nano-materials such as steel fiber, glass fiber, polymeric fiber, carbon fiber, and carbon nanotubes (CNTs) and graphene oxide (GO). However, each of these technologies has its strengths and weaknesses.

One of the recently used methods to strengthen the cement mixture and activation of cement-hydration reaction is application of microbubbles to the mixing water. Nanobubbles increase pH, Dissolved Oxygen (DO), Electrical Conductivity (EC), turbidity, and nitrogen content in water, resulting in compressive strength improvement of cement compared to that when using water. The most important features of nanobubbles is very low production costs, high speed production, and its availability at any place and time.

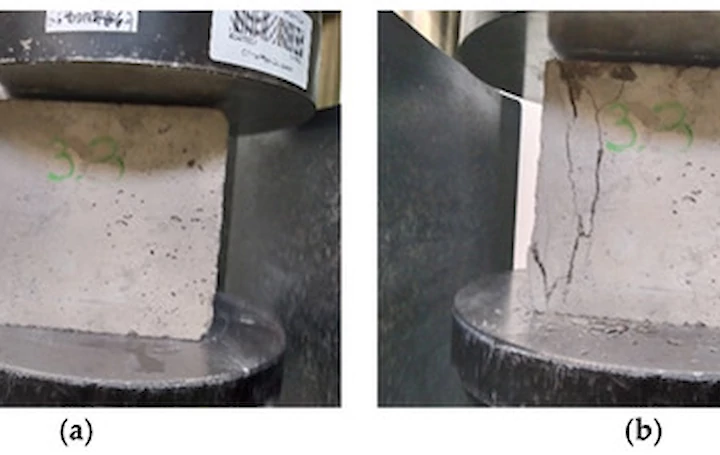

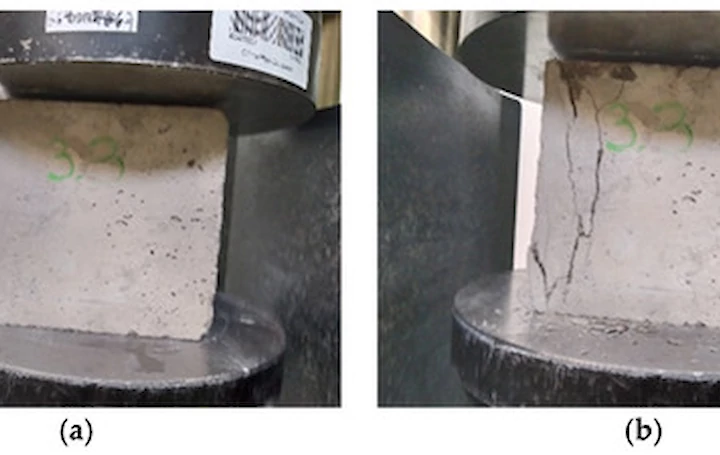

According to several studies, the application of nanobubbles improved the mechanical properties of concrete such as compressive and tensile strength. One of the studies shows that application of nanobubbles increases the compression and tensile strength of concrete up to 16% and 19% respectively. Another related research shows that using oxygen-nanobubbles increases the mechanical strength of concretes up to 61% compared concrete made with plain tap water (Fig.1, 2).

Acniti offers the best nanobubbles instruments to produce sufficient oxygen-nanobubbles. She produces products for different industries and fields including construction companies.

Another important point is application of nanobubbles and some other materials such as zeolite and Chekneh pozzolan in the concrete instead of cement and general water. One recent research shows that the mixture of zeolite, chekneh pozzolan, and nanobubbles water significantly improved the strength and durability of the concrete, which is a meaningful alternative to cement and mixing water to reduce air pollution, increase concrete performance, and reduce concrete production costs.

Conclusion

- Concrete is the main part of building materials.

- Nanobubbles technology is applicable in various fields including surface coating and cleaning, removal of pollutants, water treatment, biomedical and contraction engineering, improving the flotation of ultrafine minerals, and the release of energy when the bubbles collapse and destroyed.

- Application of nanobubbles improved the mechanical properties of concrete such as compressive and tensile strength up to 60%.

- Nanobubbles technology is the best, cheapest, simplest and safest way to improve the mechanical feature of constructional materials.

- Acniti offers high quality oxygen- nanobubbles instruments to produce sufficient oxygen-nanobubbles for construction companies and individuals.