Published: Wednesday, 12 February 2020

Modified: Thursday, 27 March 2025

How to measure nanobubbles?

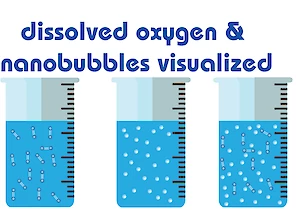

Before evaluating how fine bubbles work, it is important to know what size distribution and which number concentration of fine bubbles you are using. When you notice it works, you should know the minimum required concentration and/or size distribution. This enables you to optimize generating fine bubbles not to waste the time of generation and minimize the system size. On the other hand, there are applications which require higher concentration than 100M/ml and you cannot tell there is no effect by using Ultrafine bubbles generating machine which makes 50M/ml concentration.

We need to be careful enough about fine bubbles concentration. Fine bubbles can be measured by the same technology of measuring small particles. You can measure MB by camera (count pixel size) or laser (count blackout time), also as a simple method to know number index, you can refer information of turbidity. When starting out measuring nanobubbles always use Nitrogene gas as this is the easiest gas to measure nanobubbles followed by air and oxygen. Becare using ozone gas as these might break your equipment, so check the manual first.

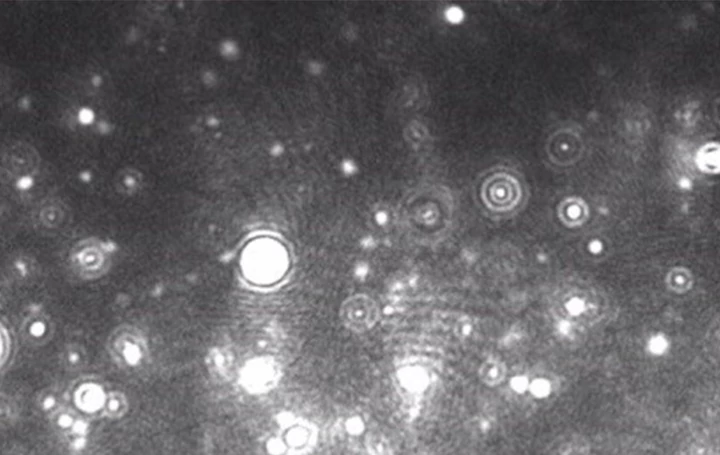

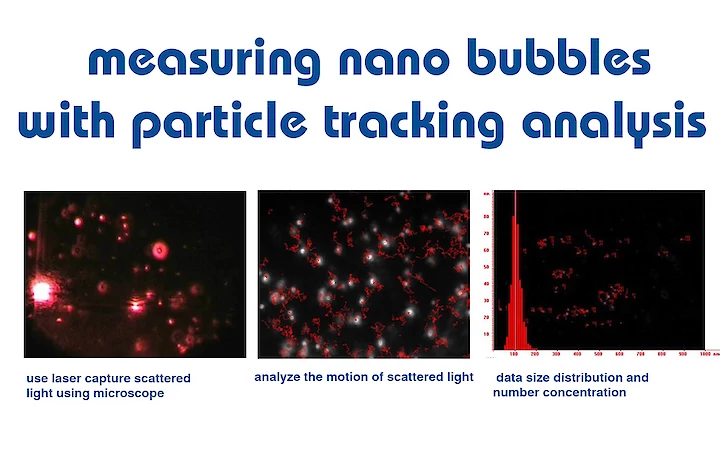

When you measure nanobubbles, the most common way is to analyze Brownian Motion. Use laser and microscope to catch scattered light from UFB, take video and analyze how fast each UFB moves. (It is called Particle Tracking Analysis =PTA). As you know, Brownian Motion speed does not depend on the type of material but only by size, liquid temperature, and viscosity of liquid. When you know liquid temperature and viscosity. We conclude fast Brownian motion means small Ultrafine bubbles and slow ones means relatively bigger Ultrafine bubbles. By tracking the Brownian motion, you will know the size of each Ultrafine bubble.

Commercial Measuring devices for nanobubbles?

Discovery and development of nanobubble generators was slow in the past because it was difficult to measure nanobubbles. Based on equipment available in the market to measure particles the same measurement methods were used to measure nanobubbles but not without issues.

| Manufacturer | Product | lower limit (particle) | lower limit (bubble) | Measurement system |

| Malvern NanoSight | NanoSight NS300 / NS500 | 10nm | 60nm | Particle tracking analysis |

| Shimadzu | SALD7500-nano | 7nm | Laser diffraction scattering | |

| Shimadzu | SALD7100HH | 100nm | Laser diffraction scattering | |

| Sympatec | HELOS | 100nm | Laser diffraction scattering | |

| Malvern Instruments | Zetasizer Nano | Dynamic light scattering | ||

| Otsuka Electronics | ELSZ-2plus | Dynamic light scattering | ||

| Sympatec | NANOPHOX | Dynamic light scattering | ||

| Archimedes | Affinity Biosensors | Resonant mass measurement | ||

| IZON | qNano | Electrical sensing zone | ||

| Beckman Coulter | Multisizer 4 | Electrical sensing zone | ||

| Micromeritics | Elzone II 5390 | Electrical sensing zone | ||

| Horiba | ViewSizer 3000 | 10nm | 60nm | Particle tracking analysis |

In theory all the above equipment should be able to measure nanobubbles but there is a catch. When measuring particles this will give a strong diffracted laser to the detection sensor so it can be measured. On the other hand, when measuring nanobubbles they are very dark against the detection's sensor. This results that many nanobubbles not being detected. I.e., the NanoSight NS500 can measure particles down to a limit of 10nm, but when it comes to nanobubbles the detection limit goes up to maybe 60nm. Many of the other measurement equipment manufacturers can only detect larger particles / bubbles, as the mode diameter for nanobubbles is always somewhere between 50~90nm they will simply miss all or a very large part of the nanobubbles. Other equipment manufacturers can only measure nanobubbel when the concentration of nanobubbles is larger than 7 billion so keep this in mind when preparing your sample.

Sometimes our university and research clients come back to us saying the nanobubble generator is not working. The reason most of the time is not that the nanobubble generator is at fault but the measurement method has flaws. So far in Japan as we know, only two measurement products are used for properly detecting nanobubbles. The Shimadzu SALD7500-nano and the NanoSight NS300. Please be careful with the NanoSight as this comes with 4 types of lasers, red 642nm, green 532nm, blue 488nm and violet 405nm. For the NanoSight only the λ 405nm laser will work properly.

A measurement protocol for ultrafine bubbles can be obtained from ISO.

Do you have any other experiences with measuring nanobubbles or find any incorrect information please drop us a note and we will correct and update this article.

ALT Ultrafine bubble sensor

NanoSight with the particle tracking analysis method is probably the most widely used measurement instrument for ultrafine bubbles. But also, Shimadzu with the Sald7100HH can measure ultrafine bubbles. The downside of this equipment is that it's relatively expensive and not suitable for process monitoring. Many clients are looking for a more economical solution to get an indication if their ultrafine bubble generator is working perfectly and to save costs and energy when high levels of ultrafine bubbles are reached equipment should stop automatically. The ALT-9F17 is an ultrafine bubble sensor system based on the scattered laser principle.