nanobubbles pressurized dissolution method

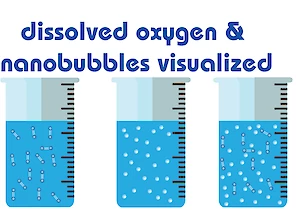

The pressurized dissolution technique is one of two major nanobubbles generation techniques. Gas-water circulation is the other technology. All nanobubble generators are based on one or the other technology or a combination of both. Pressurized dissolution technology is a well patented method. The pressurized dissolution or more practically gas-water pressurization-decompression technology contains 4 steps. See image on the right.

- Liquid is pumped into the unit under pressure.

- By narrowing the size of the pipe, the speed of the incoming liquid flow is increased, which converts most of the pump pressure into dynamic pressure, thus reducing static pressure and air being suctioned through negative pressure.

- After the liquid and suctioned gas become saturated with bubbles, the liquid/gas flow is sent through a wider pipe to reduce the speed of the flow, where dynamic pressure is converted back to static pressure and the process of pressurized dissolution of gas takes place.

- After the gas is completely dissolved into the liquid, the liquid/gas is ejected at once using atmospheric pressure, causing the liquid to become over-saturated, and massive ultra fine nano-bubbles are released.

Links

5 Links to other pages: pressurized dissolution method

There are various technologies to generate nanobubbles (ultrafine bubbles). This article gives an overview of the most used techniques, such as pressurized dissolution, static mixers, and rotational flow.

High concentration nanobubble generator, producing the highest concentration of bubbles in the industry. Creates billions of nanobubbles in water.

The miniGaLF is an entry level GaLF model designed for companies, universities, research institutes and individuals that want to learn about ultrafine bubble technology.

Customized GaLF solutions built into your own applications, this is a stainless steel model. Suitable for hydrogen and gasoline.

The miniGALF is IDEC`s entry level GaLF model designed for first experiences with nanobubble technology. The miniGaLF-Plus enables higher concentration of nanobubbles by multi-passes of water through the miniGaLF.