static mixer nanobubbles

Static Mixers and Nanobubbles: Revolutionizing Water Treatment

Static mixers, which have long been used for blending liquids in various industries, have found a transformative role in nanobubble technology. Originally designed to mix two liquids, the first static mixer patent was filed in 1965, paving the way for continuous, in-line mixing solutions in factories and processing plants. Today, static mixers are not limited to blending liquids—they also efficiently introduce gases into liquids, forming the backbone of innovative nanobubble generation systems.

From Liquid-Liquid Mixing to Gas-Liquid Applications

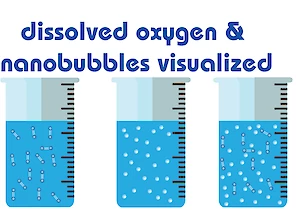

While the classic static mixer consists of a fixed set of internal elements that stir two liquids as they flow through a pipe, modern applications often involve mixing a gas with a liquid. This approach is crucial for generating nanobubbles—tiny gas bubbles measuring less than 200 nm in diameter—that remain stable in water and facilitate the enhanced dissolution of gases, such as oxygen.

Key Benefits of Static Mixers in Nanobubble Generation

- High Throughput: Static mixers can handle large volumes of water, making them ideally suited for municipal, industrial, and agricultural applications where substantial water treatment is necessary.

- Low Maintenance: Unlike mechanical agitators, static mixers have no moving parts, making them less prone to wear and virtually insensitive to clogging. This ensures operational reliability even in challenging water conditions.

- Scalable Design: Static mixers can be customized in size and configuration to suit a wide range of flow rates and pipe sizes, offering flexibility from pilot setups to full-scale water treatment plants.

The acniti Approach

The technology developed by acniti leverages the static mixer principle for nanobubble generation. By precisely introducing and dispersing gas into the flow of water, acniti systems create a stable population of nanobubbles that improve gas transfer efficiency, support aquatic life, and enhance water purification processes.

Static mixer-driven nanobubble technology showcases how a simple, yet robust engineering principle from the 1960s continues to drive innovation in water treatment for the 21st century. With benefits in efficiency, reliability, and scalability, these systems are setting new standards for environmental and industrial processes.

Links

There are various technologies to generate nanobubbles (ultrafine bubbles). This article gives an overview of the most used techniques, such as pressurized dissolution, static mixers, and rotational flow.