nanobubble generator

A nanobubble generator or as it should be called according the ISO standards, an ultrafine bubble generator is a device that mixes water and a gas and produces nanobubbles. Nanobubbles should be smaller than 200 nano meter to be called a nanobubble. Since 200 nano meters is quite large to be called nanoscopic the name nanobubbles is not completely appropriate. For this reason, the ISO has named a nanobubble an ultrafine bubble. The naming convention follows the same names as for particles.

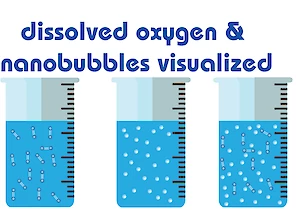

Basically, there are two types of nanobubble generators, first there are gas-water circulation types of nanobubble generators. Second there is a gas-water pressurization-decompression also often referred to as pressurized dissolution type of nanobubble generator. All units are based on one principle or the other, or a combination of both. In the gas-water circulation type the gas is introduced into a water vortex and the gas bubbles are formed by breaking the vortex. In the pressurized dissolution method, about 5% of gas is under pressure dissolved in water and forms a supersaturated solution. When the water is depressurized, the gas escapes from the water and forms nanobubbles. It's like opening a bottle of beer or a can of coke, the drink in the bottle is depressurized and bubbles are formed. The pressure in a beer or coke is to low to form any nanobubbles.

Acniti sells nanobubble generators with the gas-water circulation type, we have branded them the turbiti series. Acniti also sells the pressurized dissolution nanobubble generators, which are branded as GaLF. GaLF stands for Gas Liquid Foam.

Links

35 Links to other pages: nanobubble generator

Selecting a nanobubble generator can be a daunting task when you are new to the technology. In the following article we explain the differences of the various units. This helps you to select the best nanobubble generator for your research, application development or ultrafine bubble production.

High concentration nanobubble generator, producing the highest concentration of bubbles in the industry. Creates billions of nanobubbles in water.

In Aichi Japan 3 flower growers are interviewed about using the acniti nanobubble generator. The testimonials are recorded in summer of 2019.

Turbiti Fusion micro nanobubble generator

Turbiti nanobubble generator pump recommendations. Proper head calculations are required to effectively use the turbiti.

The hammermill-rotation concept of the microStar uses the least amount of energy in the industry to generate nanobubbles.

Customized GaLF solutions built into your own applications, this is a stainless steel model. Suitable for hydrogen and gasoline.

The miniGaLF is an entry level GaLF model designed for companies, universities, research institutes and individuals that want to learn about ultrafine bubble technology.

Ebara DWO 400 for nanobubble generator turbiti 737 and small 747 applications

Gas check valve ozone to avoid water in the ozone generator made from stainless steel 316L with viton seals

Ebara 3M 50-125/3.0 for nanobubble generator turbiti 747 and 848

A buoy for the submersible nano-bubble mixer. In this way its easy to place in the water

Gas check valve oxygen required for all nanobubble mixers to avoid water into the oxygen concentrator

The wall mounted Turbiti is the multipurpose nanobubble generator suitable for agriculture, horticulture and fish cultivation sites. Super saturation of oxygen for water day storage tanks in horticulture. Drinking water solutions for chicken, cows, pigs and horses, giving high DO water with ultrafine bubbles to animals with enhance their food digestion more efficiently and results in healthier animals.

The turbiti nanobubble generator is a first-class workhorse. Turbiti can be placed in the most demanding environments. The nanobubble generator requires a low head pump, so it's efficient in energy usage. Combined with the benefits of a static mixer, Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti into their own equipment. The Turbiti concept gives you a worry free nanobubble solution.

The ozone nanobubble mixer is a nanobubble generator which is specifically designed for the use with ozone. Research with universities has shown, that ozonated nanobubble water, keeps longer its ozone residue in the water than when it is used only with a venturi also the amount of ozone gassing out is reduced.

The Turbiti O2 pump skid is the multipurpose ultrafine bubble generator suitable for agriculture, horticulture and fish cultivation sites. Super saturation of oxygen for water day storage tanks in horticulture. Drinking water solutions for chicken, cows, pigs and horses, giving high DO water with ultrafine bubbles to animals with enhance their food digestion more efficiently and results in healthier animals.

The high quality oxiti aerator supplies 40 to 100 liter per minute of air. Depending on the depth its positioned on. Its built to run continuously for many years trouble free.

Large volume submersible ultrafine bubble generator in combination with a dissolved oxygen generator, for aerating effectively lakes, horticulture, fishponds and shrimp cultivation. Aeration is for many biological processes very important the Acniti submersible unit guarantees high DO values for ideal biological activities creating an optimal environment for high production output.

Low cost Ultrafine Bubble Monitoring ALT-9F17 system, to measure reliably the concentration of ultrafine bubbles (nanobubbles) in your water.

Oxiti industrial oxygen concentrator with high quality components from Japan and America, built in a rugged design aluminium casing. The concentrator uses pressure swing adsorption (PSA) technology and produces 8 liter per minute of oxygen. This unit gives peace of mind and many hours of stable oxygen production.

oxiti Ozone is an industrial oxygen concentrator with a built-in ozone concentrator.

There are various technologies to generate nanobubbles (ultrafine bubbles). This article gives an overview of the most used techniques, such as pressurized dissolution, static mixers, and rotational flow.

Effect of air nanobubbles on oxygen transfer, oxygen uptake, and diversity of aerobic microbial consortium in activated sludge reactors

Washing of surfaces and laundry is one of the promising areas were nanobubbles can make a difference in the application. Reducing the amount of detergent, has a positive effect by reducing pollution, washing laundry without detergent, would greatly benefit the environment. Nanobubbles can lower the surface tension of water, the large amounts of oxygen molecules in bubbles charge the water negative.

The miniGALF is IDEC`s entry level GaLF model designed for first experiences with nanobubble technology. The miniGaLF-Plus enables higher concentration of nanobubbles by multi-passes of water through the miniGaLF.

Acniti manufacturer and marketing and sales organization for nanobubble technology and industrial oxygen concentrators.

Nanobubbles can be measured by the same technology as measuring small particles. You can measure bubbles by camera (count pixel size) or laser (count blackout time), also as a simple method to know number index, you can refer information of turbidity. When you measure UFB, most common way is to analyze Brownian Motion.

A temple with a beautiful moat in Kyoto, Japan had a group of volunteers maintaining the moat, by cleaning it and doing regular maintenance. Due to the older age of the volunteers, the group stopped moat maintenance around 1998. In the next 20 years no maintenance was done and year by year the situation worsened on one hand natural pollution wasn't removed such as leaves in autumn and excessive uncontrolled water plants growth took place. On the other hand, tourism in Kyoto was on the rise and more and more, litter came in the moat. This led to an uncontrolled situation of bad smell, fish mortality opaque water and the bottom of the moat was invisible. In the summer, algal blooms were becoming more and more frequent.

Water is one of the fundamental components of life. A large part of living cells is made up of water. Birds need twice as much water as the food they eat. To satisfy the need for water in poultry and birds, you must make water freely available to them. Note that the unavailability and limitation of water consumed by poultry slows down their growth. The water used in poultry feeding should not contain parasites, bacteria, pollution or chemicals, and fresh and clean drinking water must be provided. Bacterial agents are one of the most common water-borne infections. Drinking contaminated and untreated water can cause huge losses in the poultry industry. Using chemicals and antibiotics to disinfect drinking water can cause health problems and drug resistance in chickens. In the last decade, researchers have tried to find a suitable alternative to disinfect and improve the quality of drinking water for farm animals, especially chickens. One of the most available and best options is oxygen-nanobubbles water. By providing oxygen- nanobubbles water, the growth and development of chickens increases, and on the other hand, it enhances their resistance against microbial infections. In this article, we evaluate the benefits of oxygen-nanobubbles water in the poultry industry.

Oxygen plays an important role in plant respiration, which causes energy production and plant growth. Increasing the percentage of oxygen in water improves the root structure and the activity of useful microbes in the rhizosphere. Naturally, an effective and practical system can increase productivity by improving the quality of irrigation water and increasing dissolved oxygen in irrigation water. Acniti oxygen concentrator and Acniti turbiti O3 are very effective supplements for irrigation of agricultural fields and at the same time improve water quality and increase dissolved oxygen (DO) and ozone in irrigation water. To determine the role of oxygen and ozone nanobubbles in the growth of lettuce, an experimental research was conducted. Research showed that by using Acniti nanobubbles generators, will increase the level of dissolved oxygen in water, and makes the roots of lettuce grow more and its weight increases significantly.

Combined with the benefits of a static mixer Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively ozone nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti ozone technology into their own equipment and sell nanobubbles generator equipment under their own brand name. This product is only for dealers and partner of acniti, that have a license agreement and commit to buy certain quantities.

Great things happen when the world agrees, fine bubbles are an innovative technology, but without proper standards for the industry development, there are obstacles. From 2013 ISO started the creation of an International Standard for fine bubbles popularly know as nanobubbles.

Acniti parts are supporting products and spare parts for oxygen concentrators, nanobubble generators and inlet filters.

Accessories for turbiti nanobubble generator