Modified: Saturday, 21 February 2026

Written by Erik van Berkum (LinkedIn)

Nanobubbles vs. Corrosion: Transforming Chiller Maintenance with Nitrogen Microbubbles

A Persistent Problem for Chiller Owners

Under-deposit corrosion is a notorious culprit in chiller and cooling system maintenance. Especially in systems that cycle on and off or stand idle for long stretches, deposits lead to pockets of high local oxygen concentration where corrosion thrives. Traditionally, facility managers rely on coatings, sacrificial anodes, and frequent circulation routines, but these measures are either labor-intensive, environmentally taxing, or only partly effective.

At Acniti, we see a different future for water treatment—a future delivered by advanced nanobubble technology. What if there was a way to create a protective environment inside your chiller system without relying on chemicals or constant manual intervention? That's where Nitrogen nanobubbles come in.

Why Nitrogen Nanobubbles?

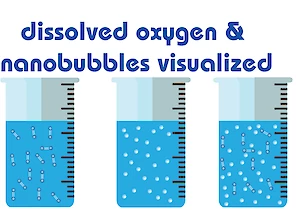

Unlike conventional gas blanketing with Nitrogen—which sits atop the water or circulates in the headspace—nanobubbles penetrate every corner of your chiller's water network. With diameters under 200 nanometers, these stable, buoyant bubbles remain suspended in water for extended periods, moving effortlessly through deposits, films, and even into micro-crevices.

Research shows Nitrogen nanobubbles displace dissolved oxygen from beneath deposits far more effectively than traditional Nitrogen purging. This oxygen-starved layer directly blocks the electrochemical reactions that cause under-deposit corrosion on metal surfaces. In chiller tubes, that means a drastic reduction of the pitting and wall thinning that cause unexpected leaks and costly repairs.

Results That Speak for Themselves

Peer-reviewed studies support impressive numbers: Nitrogen nanobubble technology achieves corrosion inhibition rates of 80–95%, notably higher than gas blanketing alone or even many advanced coatings. These results aren't just from the lab: power stations and industrial cooling networks have seen significant drops in cleaning and maintenance frequency after adding nanobubble systems to their water loops.

What's more, nanobubble injection also interrupts the microbial activity that leads to biofilm buildup and scaling—two persistent problems that further reduce heat transfer efficiency and accelerate corrosion. By lowering both biological and chemical threats, these systems deliver a double benefit: longer intervals between scheduled maintenance and more efficient system operation.

Practicality for Retrofit and New Builds

One common concern: Is nanobubble technology difficult to implement? Fortunately, it's not. A Nitrogen nanobubble generator (like Acniti's Turbiti series) connects as a sidestream to your chiller system, treating a portion of the circulating water continuously. There's no need to overhaul piping or take the chiller offline for weeks—installation is straightforward, with clear ROI for both new builds and retrofits.

Savings stack up steadily: although nanobubble systems involve higher up-front investments than basic chemical dosing, their overall 10-year cost of ownership is typically the lowest among modern anti-corrosion solutions. Expect reduced chemical use, fewer equipment replacements, and fewer emergency callouts.

What’s Next for Cooling Systems?

As water treatment becomes more sustainable and regulations tighten, Nitrogen nanobubbles answer the call for innovative, low-impact corrosion prevention. Continuous oxygen stripping without harmful byproducts? Check. Lower risk of microbial fouling and scaling? Absolutely.

Suppose you're facing persistent chiller tube failures or want to shift to a long-term, lower-maintenance solution. In that case, it’s time to explore what nanobubbles can do for your system's reliability and for your bottom line.

Curious about practical retrofitting steps, or want to see data from sites already using nanobubbles?

Contact Acniti to discuss how our Nitrogen nanobubble technology can help upgrade your water treatment strategy.