Modified: Thursday, 22 January 2026

Written by Erik van Berkum (LinkedIn)

Generating High-Concentration Nanobubbles with the miniGaLF Plus

Entry level Gas-Liquid Interface Research

The miniGaLF is IDEC`s entry level GaLF model designed for companies, universities, research institutes and people who want to learn about nanobubble technology. The miniGaLF provides a lot of possibilities to design your own nanobubble application as it is easy to fit and retrofit in existing machines and processes. In the simplest setup just connect the miniGaLF to your water tap and add a gas source either from a compressor or a gas cylinder with pressure regulator, and you are ready to go. In the more advanced setup, you can add a recirculation system to make higher concentrations of nanobubble water, which we call -Plus. The -Plus version requires a check valve a pump, a recirculation tank.

Why Nanobubble Recirculation?

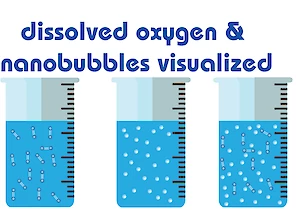

When you connect the miniGaLF straight to the water faucet, the number concentration of nanobubbles in 1 ml after one pass (1-minute run with 7.5 liters’ tank) is 70~80 million bubbles per ml. Measurement done with NanoSight at IDEC R&D facility using city tap water. When you want higher concentrations of bubbles, i.e., 100 million or more than two passes of the water through the miniGaLF are required. We call this the "miniGaLF -Plus" version.

For the "miniGaLF -Plus" model, the user needs to prepare a pump, a water tank with a water inlet and outlet, and a check valve to protect the pump and tubing. Depending on the pump you select, you might have to add an inverter box.

The miniGaLF can handle all non-corrosive gases, including air, O2, N2, and CO2. The miniGaLF is not suitable for use with ozone for disinfection applications. The miniGaLF produces bubbles intermittently, during operation it takes in only water or gas, during the gas intake which lasts about 5 seconds, the bubble generator releases no bubbles and water. After gas intake, a production cycle of approximately 45 seconds of nanobubble water will occur.

The Nanobubble Generator components

When the user application requires air in the form of nanobubbles, the easiest way is to purchase an air compressor. The air compressor requires a small tank, as tankless models are unable to deliver enough air during the gas intake period. We recommend buying the compressor locally, online, or in a home and hardware store.

To protect the tubing and the pump install a check valve, during the gas intake period, the miniGaLF doesn't take in any water, while the pump keeps running this built up a lot of pressure in the tubing and shortens the lifetime of the pump. We recommend installing a Swagelok check valve SS-8CPA2-50 or with weaker pump SS-8CPA2-RT-3, when the pressure is getting too high in the system, the check valve will open and divert the water into the re-circulation tank.

For the pump, the following general specifications are required: a minimum head of 30 meters (300 kPa). It is recommended to have a 20% extra capacity and a flow rate of 7.5 liters/minute. Two pumps with the correct specifications are the Ebara PRA 0.50 and the Lowara PM21. The Ebara PRA 0.50 is suitable for customers who have 115V or 230V power available for the pump. The Ebara pump must be used in combination with a frequency drive so the pump speed can be set according to your needs.

When you feel, after reading this blog post, that the plumbing and electrical work for the additional components is too overwhelming, we recommend considering the high-concentration GaLF model, as it is an all-in-one solution. It doesn't require a compressor and features a built-in pump.