static mixer nanobubbles

The static mixer has its origin from mixing two liquids, the first patent for a static mixer was filed in 1965. Instead of mixing two liquids, there is also the possibility of mixing a liquid and a gas. The benefits of the static mixers is that they can treat large volumes of water at once. They are not sensitive to clogging. The acniti technology is based on this principle.

Links

4 Links to other pages: static mixer

Combined with the benefits of a static mixer Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively ozone nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti ozone technology into their own equipment and sell nanobubbles generator equipment under their own brand name. This product is only for dealers and partner of acniti, that have a license agreement and commit to buy certain quantities.

The turbiti nanobubble generator is a first-class workhorse. Turbiti can be placed in the most demanding environments. The nanobubble generator requires a low head pump, so it's efficient in energy usage. Combined with the benefits of a static mixer, Acniti has implemented their proprietary swirl flow technology to generate efficiently and effectively nanobubbles. The turbiti OEM series gives dealers and partners the opportunity to implement the turbiti into their own equipment. The Turbiti concept gives you a worry free nanobubble solution.

The wall mounted Turbiti is the multipurpose nanobubble generator suitable for agriculture, horticulture and fish cultivation sites. Super saturation of oxygen for water day storage tanks in horticulture. Drinking water solutions for chicken, cows, pigs and horses, giving high DO water with ultrafine bubbles to animals with enhance their food digestion more efficiently and results in healthier animals.

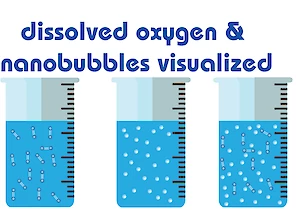

There are various technologies to generate nanobubbles (ultrafine bubbles). This article gives an overview of the most used techniques, such as pressurized dissolution, static mixers, and rotational flow.