Links

7 Links to other pages: drinking water

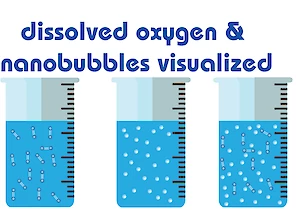

Water is one of the fundamental components of life. A large part of living cells is made up of water. Birds need twice as much water as the food they eat. To satisfy the need for water in poultry and birds, you must make water freely available to them. Note that the unavailability and limitation of water consumed by poultry slows down their growth. The water used in poultry feeding should not contain parasites, bacteria, pollution or chemicals, and fresh and clean drinking water must be provided. Bacterial agents are one of the most common water-borne infections. Drinking contaminated and untreated water can cause huge losses in the poultry industry. Using chemicals and antibiotics to disinfect drinking water can cause health problems and drug resistance in chickens. In the last decade, researchers have tried to find a suitable alternative to disinfect and improve the quality of drinking water for farm animals, especially chickens. One of the most available and best options is oxygen-nanobubbles water. By providing oxygen- nanobubbles water, the growth and development of chickens increases, and on the other hand, it enhances their resistance against microbial infections. In this article, we evaluate the benefits of oxygen-nanobubbles water in the poultry industry.

Advanced Ozone Water Sensor EL-610 series based on UV absorption technology

Nanobubble Ozonation is a highly effective water treatment process that utilizes ozone's powerful oxidizing properties to disinfect water, eliminate viruses, bacteria, and other pathogens. It also removes contaminants like iron and manganese, improving taste and odor. This method generates no harmful residuals, making it an eco-friendly choice for safe drinking water preparation.

Discover the advanced Underwater Oxidant Meter designed for fast, accurate measurement of oxidants like chlorine and ozone in salt or brackish water—without the need for reagents. Its innovative self-cleaning and three-electrode technology ensure highly reliable performance, even in challenging marine environments. Learn how this rugged, easy-to-maintain instrument sets a new standard for water quality monitoring in industrial, environmental, and research applications.

The ECLG‑35 Residual Chlorine Meter is a high-precision, reagent-free sensor designed for continuous monitoring of free residual chlorine in drinking water and industrial water systems. Utilizing a 3-electrode pulse voltammetry method, the ECLG-35 offers accurate and stable measurements without the use of chemical reagents, significantly reducing operational costs and environmental impact. The sensor features an advanced automatic cleaning system, combining bead flow and electrolytic cleaning to maintain consistent sensitivity and minimize drift over time. With a measuring range of 0.00–3.00 mg/L, high repeatability (±2% FS), and a fast response time (T90 ≤ 1 minute), the ECLG-35 ensures reliable chlorine control under varying water conditions. This unit is equipped with automatic temperature compensation and a built-in thermistor, ensuring stable performance across a wide pH and conductivity range. Installation is flexible: wall-mounting is standard, or optional pipe-mounting is available on Ø50 mm tubing. Ideal for use in water treatment plants, distribution networks, buildings, hospitals, hotels, and food or pharmaceutical industries, the ECLG‑35 provides peace of mind in water safety and regulatory compliance — all while operating without consumables or complex maintenance procedures. If you need a durable, low-maintenance chlorine meter that delivers long-term accuracy and efficiency, the ECLG‑35 is the wise choice.