ナノバブル生成の革新的技術

ナノバブルの作り方

気泡を作るには、液体の中に気体を入れます。気泡は液滴の一種で、液滴とは気体中の小さな滴です。気泡および液滴ファミリーのもう1つのメンバーは、気体または液体中の固体である粒子です。これら3つの用語をそれぞれ区別することが泡の定義付けに重要です。気泡を作るには、流体力学的、音響学的、光学的、および粒子キャビテーションによる方法があります。ウルトラファインバブルを作るための最も費用対効果が高く、最も効率的なのは流体力学的方法です。流体力学は、流体上の運動と、流体に浸漬され、流体に対して運動する固体に作用する力を扱う物理学の分野です。簡単に言うと、気泡を作るには動く液体が必要で、気体を加えて気体と液体に力を加えると気泡が発生します。日常生活において、缶ビールやコーラを開けると、圧力の変化(力)によって泡が発生し、それが目と音でわかります。

ナノバブルに関する論文が初めて発表されたのは1982年で、近年までナノバブルの存在は激しく議論されていました。最近になりウルトラファインバブル技術またはナノバブル技術がもてはやされるよいうになったには2つの要因があります。第一に、ウルトラファインバブルのサイズと密度を測定できる装置が市場に出回り、現在では科学者のほとんどがナノバブルが存在することに同意しています。第二に、この測定装置の大きな利点は、ウルトラファインバブルメーカーがウルトラファインバブル発生装置をさらに開発、最適化し、装置をさらに改良できるようになったということです。

ナノバブルの生成技術には大きく分けて2種類あり、1つは気体・水循環型のナノバブル発生器です。2つ目は、加圧溶解式ナノバブル発生器とも呼ばれる気体・水の加圧・減圧方式です。ほとんどの装置は、どちらかの原則、または両方の組み合わせに基づいています。

ファインバブルの製造方法には次のようなものがあります。最初の 4 つの方法について詳しく説明します。

- 加圧溶解式

- 旋回液流式

- スタティックミキサ式

- エジェクタノズル式

- 超音波式(超音波振動)

- 発振器式

- ベンチュリ式

- 混合蒸気直接接触凝縮式

加圧溶解式

このウルトラファインバブル生成方法は、気体の濃度と分圧を関係付けるヘンリーの法則の原理に基づいています。これは、より高い圧力でより多くの気体を溶液に溶解できることを意味します。ウルトラファインバブル発生器の原理は次のとおりです。ベンチュリシステムを介して液体と気体が混合され、次の混合ボックス内のステップで加圧によって気体が水に溶解されます。最後のステップでは、ノズルを介して水と気体が排出されます。過飽和液体ガス溶液の圧力が急激に低下することにより、気体はファインバブルやウルトラファインバブルとして液体中に放出されます。図はそのプロセスを示しています。

- 液体は加圧された状態でユニット内に送り込まれます。

- パイプのサイズを狭くすることで、流入する液体の流速が上がり、ポンプ圧力の大部分が動圧に変換されるため、静圧が下がり、負圧によって空気が吸引されます。

- 液体と吸引された気体が気泡で飽和状態になった後、液体/気体の流れは、流速を下げるために幅の広いパイプに送られ、そこで動圧が静圧に変換され、気体の加圧溶解プロセスが行われます。

- 気体が液体に完全に溶解した後、大気圧を利用して液体/気体を一気に噴出させることで、液体を過飽和状態にして大量のウルトラファインナノバブルを放出します。

旋回液流式

旋回液流式は、スワール式やスパイラル式とも呼ばれます。 ベルヌーイの定理により気泡を発生させるファインバブル発生器です。流体力学では、ベルヌーイの原理により、流体の速度の増加は、圧力の減少または流体の位置エネルギーの減少と同時に起こると述べられています。この原理は、1738 年に著書『流体力学』で発表したダニエル・ベルヌーイにちなんで名付けられました。数世紀後、ファインバブル発生器はこの原理に基づいて作られました。この技術に基づいた最初の製品は、1933年のランク・ヒルシュ・渦巻チューブです。50年後には、渦巻きジェット・フレームが続きました。1990年代半ば、日本で初めて旋回型マイクロバブルが発明されました。

ファインバブル発生器の原理は、円筒形の水槽に上から水を入れ、らせん状に下向きに水を流します。円筒の中央底部から気体が吸い込まれ、回転する水が円筒上部でせん断され、細かい気泡が発生します。しかし、ウルトラファインバブルの業界では、加圧溶解法の気泡濃度が旋回液流式よりも高いことが一般的に認知されています。

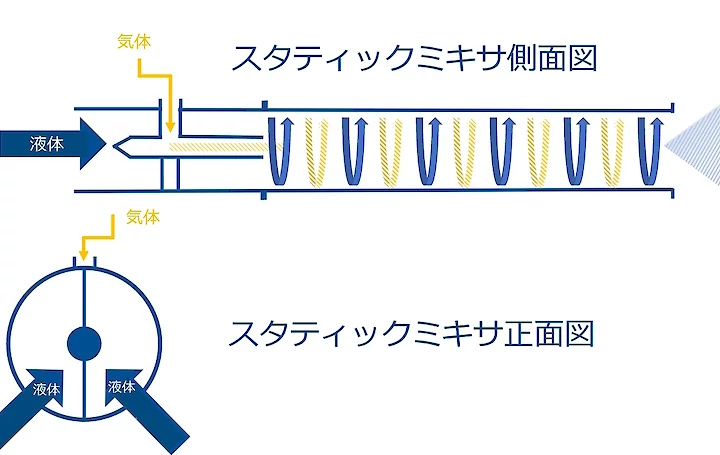

乱流スタティックミキサ式

スタティックミキサの起源は 2 つの液体を混合することにあり、スタティックミキサに関する最初の特許は1965年に出願されました。2つの液体を混合する代わりに、液体と気体を混合することも可能です。この技術は、渦を生成し、その渦の中に非常に効果的に気体を取り込むという原理に基づいています。 乱流により気体が渦を壊し、水と気体の衝突によってナノバブルが生成されます。スタティックミキサの利点は、比較的単純な設計であり、上記の他の多くのナノバブル発生装置と比較して、比較的少ないエネルギーで一度に大量の水を処理できることです。また、目詰まりの影響も受けにくいことも忘れないでください。acniti turbitiの技術は、スタティックミキサとエジェクタノズルを組み合わせたものです。

エジェクタノズル式

エジェクタノズル式ナノバブル発生器は、円筒状の発生器内の液体流路が段階的に狭窄・拡張するように設計されています。気体は最も減圧された点で負圧下に注入され、キャビテーションによって多数のナノバブルとなります。この装置では、水流は激しい乱流となり、キャビテーションが起こり気体がナノバブルと化します。エジェクタノズルは流体力学的キャビテーション式発生器と密接に関連しており、この方法では、制御された条件下で単純な形状を通る液体の流れによってキャビテーションが起こります。このナノバブル発生器内で、液体の圧力が飽和蒸気圧を下回た時、液体は沸点に達する状態になって多数の小さな気泡が発生します。 圧力が回復するとは気泡は崩壊します。キャビテーション気泡の崩壊は、衝撃波、せん断力、化学反応などの物理化学的効果を引き起こします。これらの過程でフリーラジカルが発生することがあります。

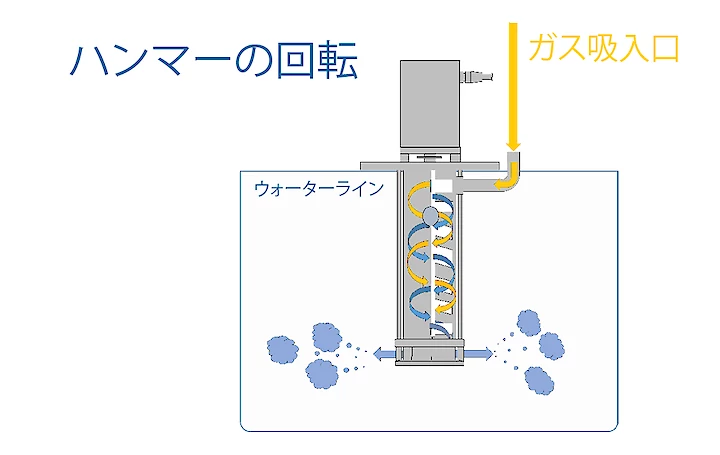

ハンマー回転方式

ハンマー回転方式の概念は、ナノバブルの生成にポンプを使用しないため、他のすべてのナノバブル生成技術と比較してユニークな概念です。代わりに、シャフトにハンマーが取り付けられたモータを使用します。モータはチューブ内で毎分3400回転の速度で回転します。チューブは上から水で満たされ、気体も上から注入されます。シャフトのハンマーがガスを溶解し、ユニットの底でガスをナノバブルに砕き、ナノバブルが出てきます。ハンマー回転方式のコンセプトは、大量の水を移動させず、高圧を必要とせず、ガスを粉砕するためにすべてのエネルギーを使用するため、ナノバブルを生成する最もエネルギーに優しい方法です。ハンマー回転式ナノバブル発生装置のラインナップは「microStarナノバブル発生器」です。オゾンガスや海水環境での使用に適した装置です。